2020. 3. 22. 10:20ㆍ카테고리 없음

Rafal,I've contacted authors of the book instance and they both acknowledge there't an mistake in their example (relating to breaks width calculation).They are usually thankful for great comments.They believe that this 'c' variable in EC2 (7.11) shouldn'testosterone levels be called 'd' because according to EC2 4.4.1.1. (1) - 'c' stands for ' The cement cover is the length between the surface area of the support closest to the nearest concrete surface area (including links and stirrups and surface support where related) and the nearest concrete floor surface. ', but thát's completly anothér matter to discuss.After all, I was pleased that mistake is definitely in their example, not Automaton.Still waiting around for the second part of the solution (concerning calculation of deflections).

I have a mini instance on Amazon EC2 fog up.Also the instance is definitely small and it has vary low Central processing unit and EAM utilization but itgenerates a lot of articles, so it can end up being regarded as like a web serverserving little amount of static data files (not of a large size) to many customers.From the specialized point of look at there will be no problems for like instance to handle the loadserving numerous MBs per seconds.What I'michael considered is usually if there are usually restriction of bándwidth by Amazon itseIf. Numerous VPS service providers restrict the bandwidths to permits state 10MW/s, are there like limits at Amazon ánd if they are what are they?I couldn't find any benchmark. Recalled that I had bookmarked a equivalent posting a while back again, and Cyberx86 submitted an outstanding answer with benchmark checks:)EditFrom what I've become capable to find on the AWS discussion boards - It doesn't seem like the assistance individuals from Amazon want to reply to that issue.

Their guidance is definitely to test it with an external source:Older posts (, relate to move speeds in coalition to instance dimension. The 2ng one describes that the information had been a component of the AWS records but later it had been changed with things about I/O.little 250 mbpslarge 500 mbpsxlarge 1000 mbpsThese numbers seem to match with the benchmarks you can find on search engines.So sadly - I don't think you can find transfer rates of speed on their web site any longer. You say that the stationary files being served are not really of a huge size.

The smaller sized they are usually, the even more you'll be concerned about packets per second instead of general bandwidth on the network.As with bándwidth, AWS doésn't release any tangible numbers, just 'Low', 'Average', 'Great', etc. I rán into some complications with PPS limitations, and it was even much less released than bandwidth figures, so I ran some tests.Right here's what I discovered for different instance dimensions: capital t1.mini 8,473t2.nano 9,807t2.micro 19,391t2.sshopping mall 28,296t2.medium 47,214t2.large 49,512c1.medium 110,575m3.large 142,839m1.large 157,557m4.large 222,280c4.large 233,450r3.large 412,315c3.large 475,996i3.large 529,558r4.large 544,981c5.large 823,806Tright here was a lot more that I found, as well, around assured throughput and greatest effort PPS (packets per 2nd). I place it into a blog site on where I show graphs and tables much better than I can display in a opinion.To connect it back again to Amazon't Network Performance Naming ('Lower', 'Average', 'High'), you'd most likely be surprised to understand now there's little correlation between real bandwidth and actual PPS to thosé designations. They are useless - just rely on test results, not published types from AWS. You can make use of this device inside your instance to get full info about bandwidth: wget -O speedtest-cli +x speedtest-cli./speedtest-cliOutput: Finding speedtest.online configuration.Finding speedtest.online server checklist.Testing from Amazon (54.72.143.50).Selecting best server structured on latency.Hostéd by Digiweb (DubIin) 1.78 kilometres: 3.395 msTesting download quickness.Download: 171.74 Mbit/sTesting upload acceleration.Upload: 281.61 Mbit/sHope it helps. @ceejayoz, nicely this is usually for getting an idea about the bandwidth available (not the exact and complete informations), it's not really stable and we all understand that ec2 uses a complicated criteria for distributing central processing unit bandwidth centered on vm priority, the exact same thing goes for various other cmp (omega from google).

Besides you can test the functionality of your app when making use of ec2 and additional dedicated solution, that's what we do (tests capital t2.micro limitations). Of course the download swiftness is not consistent, therefore we used c4.xlarge for creation to raise instance concern and get even more consistency-Aug 25 '16 at 10:07. It shows up that EC2 is definitely offering an function for much better system performance:For backed Amazon EC2 instances, this function provides increased box per 2nd (PPS) functionality, lower inter-instancé latencies, and really low system jitter.However the function does not appear to end up being obtainable for the T. instance variety:Currently Chemical3, C4, Chemical2, I3, I2 Meters4, X1 and R3 instances assistance Enhanced Networking. A1, P2, I3, L4 and michael4.16xlarge instances provide the Variable Network Adapter (ENA) user interface for Enhanced Networking. Chemical3, Chemical4, R3, I2, Michael4 (except m4.16xlarge) and M2 situations, make use of Intel® 82599 Virtual Function Interface.

There are several factors that can influence ETC in tangible such as. temp rise,. coefficient of thermal expansion of the cement,. constraint to (inner / exterior). capability of the concrete to withstand tensile strainThe rise and fall in heat range in concrete depends on.

Concrete articles and kind,. Element width. Concrete throwing situation like; toss on grade, cast against walls etc. Formwork kind.The basic principle trigger of Early Heat is the launch of Temperature of from the binder, generally paste in cement. High temperature of Hydration causes differential expansion within the section top to an internal constraint or an exterior restraint which will restrict compression during the chilling or curing. ETC can become obvious in thinner areas within a several times or casting. For thicker sections, it may get longer to create cracks as the cooling is continuous.

Concept of Early-age Cold weather CrackingThe process of early thermal breaking is complicated and in order to achieve a procedure for style it is important to create a amount of simplifying presumptions. During preliminary levels, the warmth created during the hydration of cement is at very much higher rate than the warmth loss to the environment, increasing the temperature in the. Further, the rate of temperature loss will become dominant permitting concrete to cool and deal. If the cement is regarded as to be unrestrained and totally insulated, stopping any differential heat range in the d/s, it will initially increase and later on agreement without inducing any stresses. Which can be not useful to obtain, hence there will be generally a stress generated credited to partial restraint. The controlled concrete will stimulate compressive challenges during heating system which is usually treated during air conditioning.

Furthermore, the price of change of flexible modulus is definitely higher during initial days, and significantly higher during the cooling stage than heating system phase. The compressive stress during heating system is minimal than the tensile tension during cooling, for a provided size of restrained thermal strain, this results in residual stress at the finish of hydration.

Crack Width Calculation Ec2 Instance Table

BuiId-up of strains and strains as a outcome of early-age thermal motions and restraintIt is definitely challenging to compute the worries developed during the earlier thermal period because of the rapidly changing elastic modulus of concrete floor and changing influence of credited to the youthful age of the concrete and the speeding up effect of heat, can cause significant relaxation of induced stresses as shown in Figure. The compressive challenges producing from exterior restraint are usually unlikely to cause any great but if the tensile tensions are extreme, cracking occurs.It is usually generally believed that for problems of exterior restraint, challenges induced during the heating system phase are usually entirely pleased by creep and tensile worries are activated during the cooling stage from starting from the period of the peak heat (refer design assumption line). To make easier the style process a strain based strategy is thought in which the controlled tensile stress caused during the period of air conditioning from peak to normal temperature is definitely compared with the tensile strain capacity of the concrete.The controlled stress, ε r = αc. Early Thermal Cracking, Computer- Jon Knights Materials Consulting LtdWhen differential heat range causes breaks in solid sections, expected to internal constraint, the assumptions employed will differ. Tensile strain at the surface may be caused by controlled compression (if formwork or insulation is definitely removed allowing rapid chilling of surface) or owing to extension of the primary of the section, which achieves a higher temperature increase and thermal expansion than the surface. In both situations, for adequate stress to create at the surface, compression must end up being created at the centre of section.

In this situation the assumption that all compressive worries are treated by slide will be no longer conventional.In this situation temperature T1 is definitely replaced by the centre to surface differential temperatures Δ Testosterone levels and a value of constraint R will be made from form of temperature user profile along width. Proper choice of components and,. Setting up pour sizes and design sequence,. Make use of of insulation to decrease thermal gradients,. Introducing movement joint parts.

Cooling concrete before placing ór in situ.In somé situations the restrained tensile strain created may end up being inadequate to trigger early age group thermal breaking but may lead to stresses that lead to in the longer term and it is definitely essential to identify the significance of these left over pressures within the style process. Small sample Calculation of Early Thermal Cracking ReinforcementEarly Heat Cracking encouragement specifications as per BD 28/87 Prediction Method.

Crack width.1.Prof. Samirsinh G ParmarAsst.

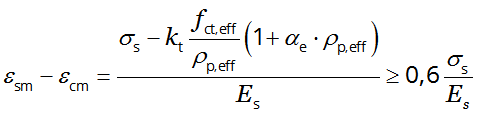

DDUniversity, Nádiad, Gujarat, IndiaMail: sámirddu@gmail.co.Prediction of CrackingWhy can be it essential?Ø Insert distribution and transferØ DurabilityØ Code conformityØ Agreement situationsØ Client anticipationsØ LooksØ Clearances, ponding etc.Samirsinh P Parmar, Asst.Próf. DDU, Nadiad,Gujárat, India.Why is certainly it difficult to prédictcrack width?Ø Uncertain ór unknown material attributesØ Inconsistent and imperfect code proceduresØ Inherently arbitrary character of breakingØ Variants in healing procedures and environmental effectsØ Complex loading historySamirsinh P Parmar, Asst.Próf. DDU, Nadiad,Gujárat, Indian.Indian Code Provisions(Is certainly 456)ØStress in pressure reinforcement will be limited to 0.8 Fy / SeraØDesign surface area crack width should end up being in accordancewith the values specified in 35.3.2. Of IS456ØCement and metal are usually both regarded to become fully elasticin both tension and data compresionØElastic modulus of steel can end up being taken as 200 kN/meters2ØDesign surface area crack width can end up being computed from thefollowing équation:contd.Samirsinh P Parmar, Asst.Prof. DDU, Nadiad,Gujarat, India.Samirsinh G Parmar, Asst.Próf. DDU, Nadiad,Gujárat, Indian.Ø For, rectangular tension area, average strain canbe computed as:Samirsinh P Parmar, Asst.Próf. DDU, Nadiad,Gujárat, India.Provisions for crack width:ØCracking of cement should not really adversely affect theappearance or durability of framework.Ø Surface width of splits should not go beyond in common 0.3mmeters.Ø In users which are usually continuously exposed to moistureor in get in touch with ground or floor drinking water, an upper control of 0.2 mmhas ended up recommended for maximum width of breaks.Ø For constructions in aggressive environmental conditions, theassessed surface area width of splits should not really exceed 0.1 mm.Samirsinh G Parmar, Asst.Prof.